- Überblick

- Product Description

- Product manufacturing process

- Fields of application

- Packaging & Shipping

- Environment & Certificates

- FAQ

- Related Porducts

Grundlegende Informationen.

Produktbeschreibung

Product Information

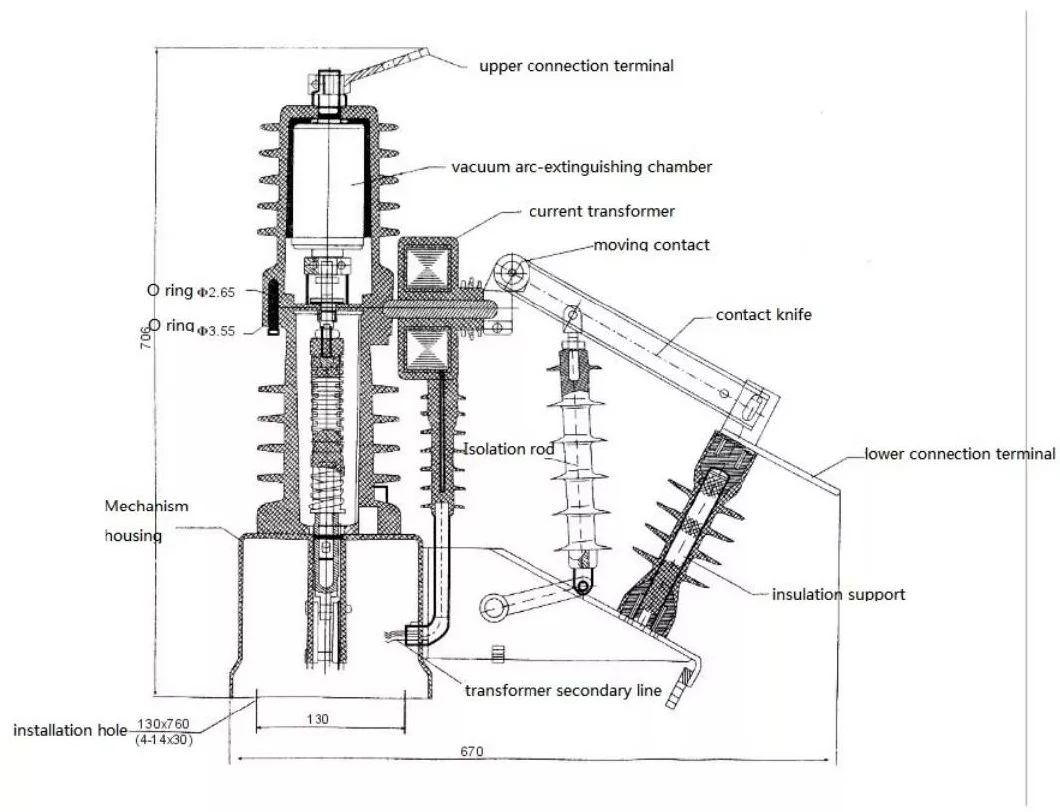

"Vacuum circuit breaker" is named for its high vacuum extinguishing medium and the insulating medium of the contact gap after arc extinguishing; It has the advantages of small size, light weight, frequent operation and no maintenance, and is widely used in distribution network. Vacuum circuit breaker is a 3-10kV, 50Hz three-phase AC system in the indoor distribution device, for industrial and mining enterprises, power plants, substations as electrical equipment protection and control, especially suitable for non-oil, less maintenance and frequent operation of the use of places. Circuit breakers can be configured in middle cabinets, double cabinets and fixed cabinets to control and protect high-voltage electrical equipment.

The vacuum circuit breaker mainly includes three parts: vacuum interrupter, electromagnetic or spring operating mechanism, bracket and other components.

Characteristic:

1.The contact opening distance is small, the contact opening distance of 10KV vacuum circuit breaker is only about 10mm, the operating work of the operating mechanism is small, the mechanical part of the stroke is small, and the mechanical life is long.

2.The arc time is short, and has nothing to do with the size of the switching current, generally only half a cycle.

3. The recovery speed of the contact gap medium after quenching is fast, and the fault performance in the near area of breaking is better.

4.Due to the small wear of the contact at breaking current, the electrical life of the contact is long, the full capacity breaking is 30-50 times, the rated current breaking is more than 5000 times, and the noise is small and suitable for frequent operation.

5. Small size, light weight.

6.Suitable for breaking capacitance load current.

Because of its many advantages, it is widely used in substations, the current models are mainly: ZN12-10, ZN28A-10, ZN65A-12, ZN12A-12, VS1, ZN30 and so on.

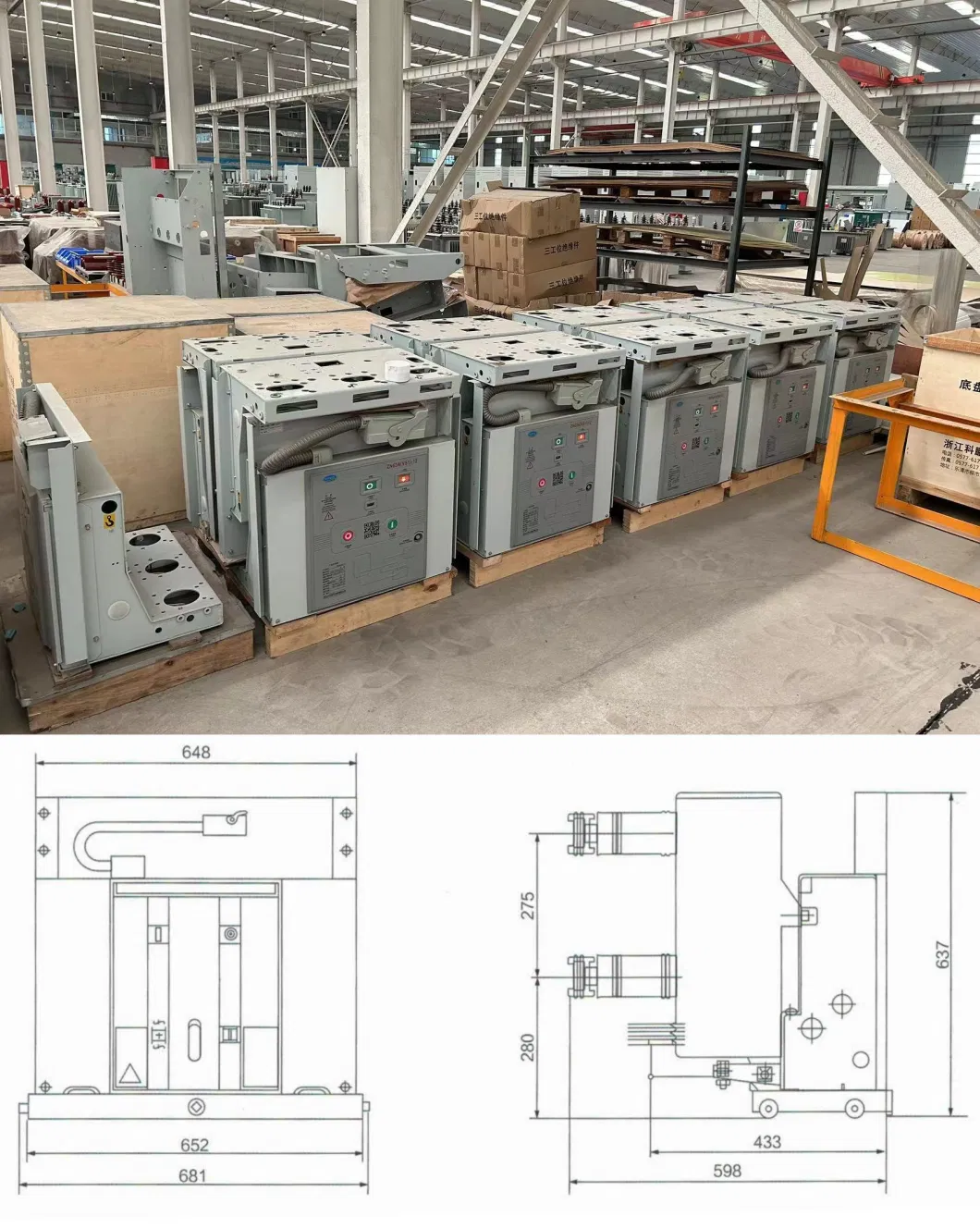

Product Details

China began to develop vacuum switches in 1958. In 1960, Xi 'an Jiaotong University and Xi 'an Switch Rectifier Factory jointly developed the first batch of 6.7 kV vacuum switches with a breaking capacity of 600 A. Then it is made into a three-phase vacuum switch with 10 kV and a breaking capacity of 1.5 kV. In 1969, Huaguang Electronic Tube Factory and Xi 'an High Voltage Electrical Apparatus Research Institute made 10 kV, 2 kV single-phase fast vacuum switch. After the 1970s, China has been able to independently develop and produce various specifications of vacuum switches.

Vacuum circuit breaker technical standard Vacuum circuit breaker has developed vigorously in China in the past ten years. The products have developed from several varieties of ZN1 to ZN5 in the past to more than dozens of models and varieties, the rated current reaches 5000A, the breaking current reaches a good level of 50kA, and has been developed to a voltage of 35kV.

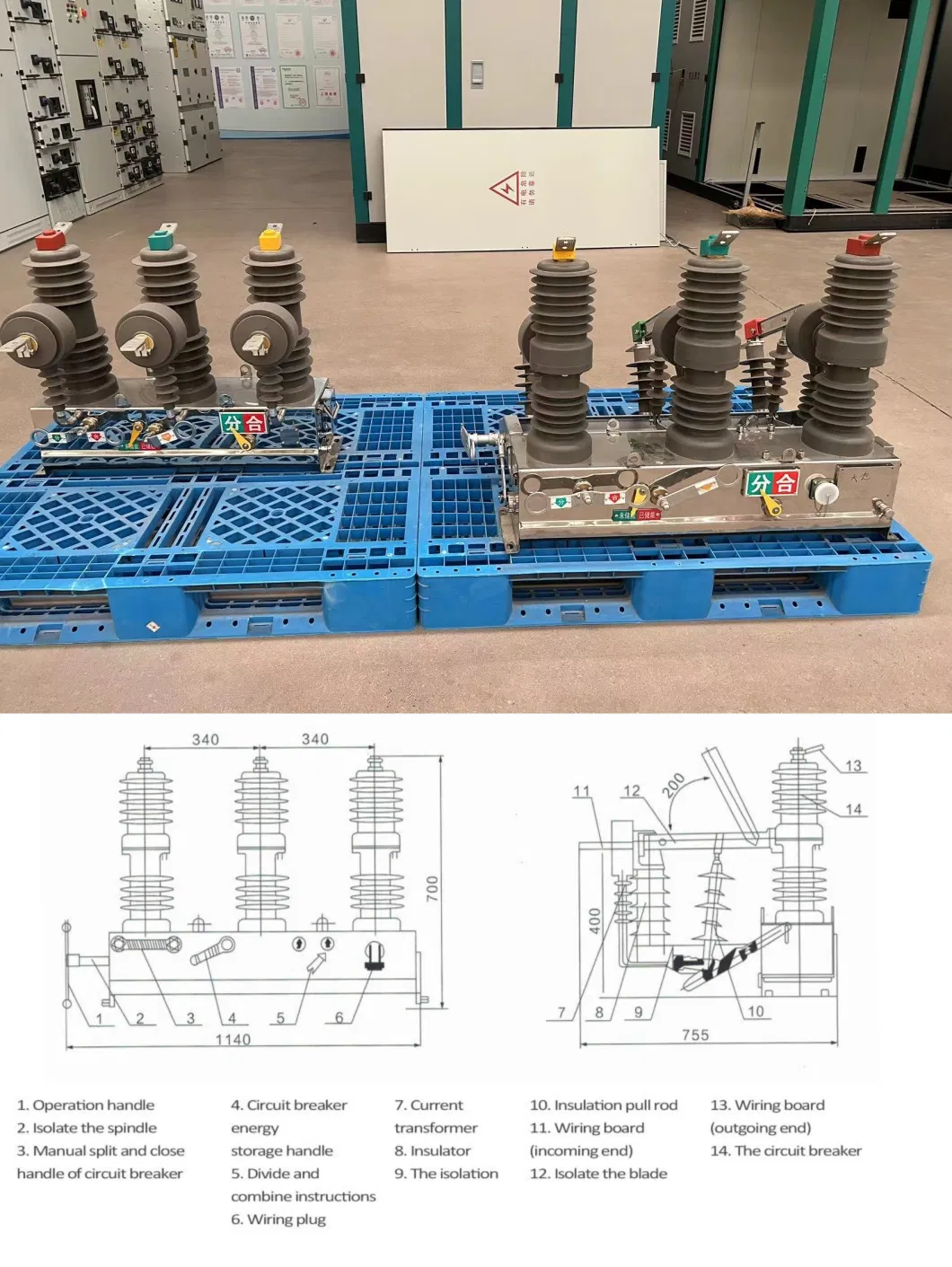

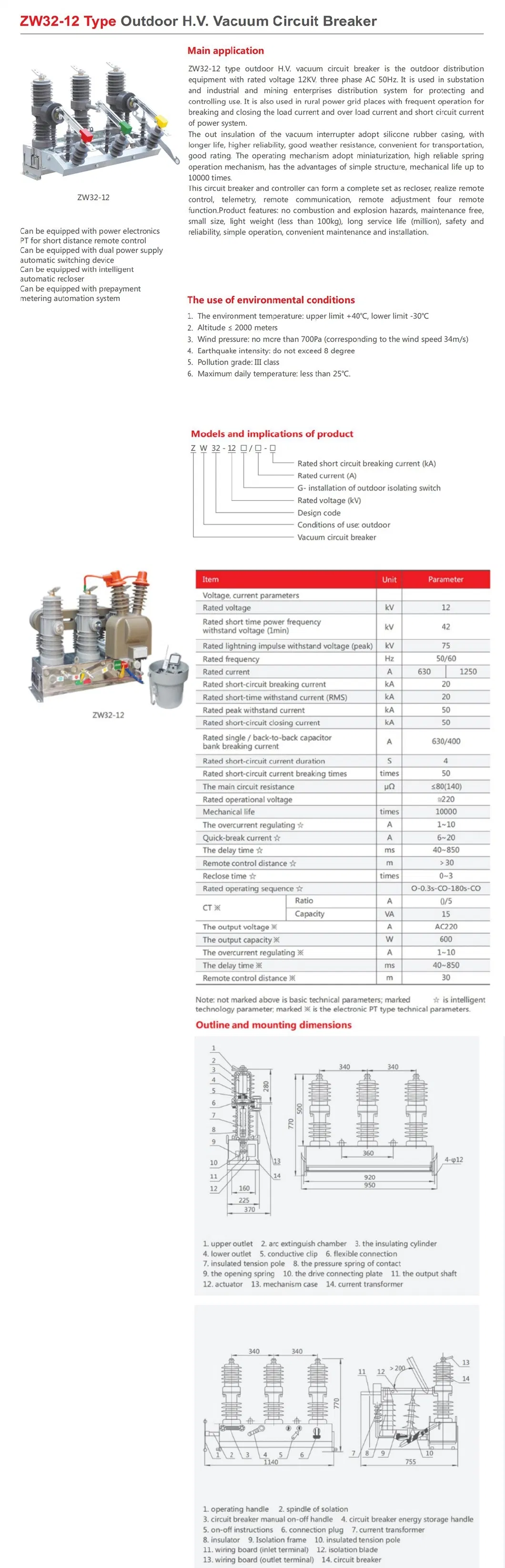

ZW32M-12 permanent magnet vacuum circuit breaker operating conditions:

1. The upper limit of ambient air temperature shall not exceed +40 ° C, the lower limit shall not exceed -25 ° C, and the 24-hour average temperature shall not exceed +35 ° C.

2. The elevation of the installation site shall not exceed <2000 meters.

3. The relative humidity of the atmosphere does not exceed 50% when the ambient air temperature is +40 ° C, and can have higher humidity at lower temperatures; When the average monthly minimum temperature of the wettest month is +25 ° C, the average maximum relative humidity is 90%, taking into account condensation on the surface of the product due to changes in humidity.

4. The pollution level is level 3.

5. There is no strong vibration and impact, no corrosive metal and harmful gases that destroy insulation, no serious dust, no conductive particles and explosive dangerous substances at the operation site.

VS1 series vacuum circuit breaker basic performance:

VS1 series vacuum circuit breaker basic performance:

1.VS1 vacuum circuit breaker can operate frequently or break short circuit current several times within the working current range; The mechanical life can be up to 30,000 times, and the full capacity short-circuit current can be broken 50 times.

2.The VS1 vacuum circuit breaker is suitable for reclosing operation and has extremely high operational reliability and service life.

3.VS1 vacuum circuit breaker (common type) uses a vertical insulation cylinder to protect against various climatic effects; In terms of maintenance and maintenance, it is usually only necessary to occasionally clean or lubricate the operating mechanism.

4.The VS1 vacuum circuit breaker (pole type) is maintenance-free with a solid insulation structure - an integrated solid seal pole.

5.VS1 vacuum circuit breaker in the switchgear installation form can be fixed, can also be withdrawable, can also be installed on the frame for use.

Product Parameters

Product Parameters

The main models of this product are as follows.

| ZW32-12 Series High Voltage Permanent Magnet Outdoor Vacuum Circuit Breaker | |||

| Serial number | Project | Unit | Parameter |

| 1 | nominal voltage | kv | 12 |

| 2 | rated frequency | hz | 50 |

| 3 | rated current | A | 630 |

| 4 | Rated short-circuit breaking current | KA | 20 |

| 5 | Rated peak tolerable current | KA | 50 |

| 6 | rated short time current | KA | 20 |

| 7 | Rated short-circuit closing current | KA | 50 |

| 8 | Rated short circuit breaking current breaking times | next | 30 |

| 9 | mechanical life | next | 10000 |

| 10 | power frequency withstand voltage | KV | 42/48 |

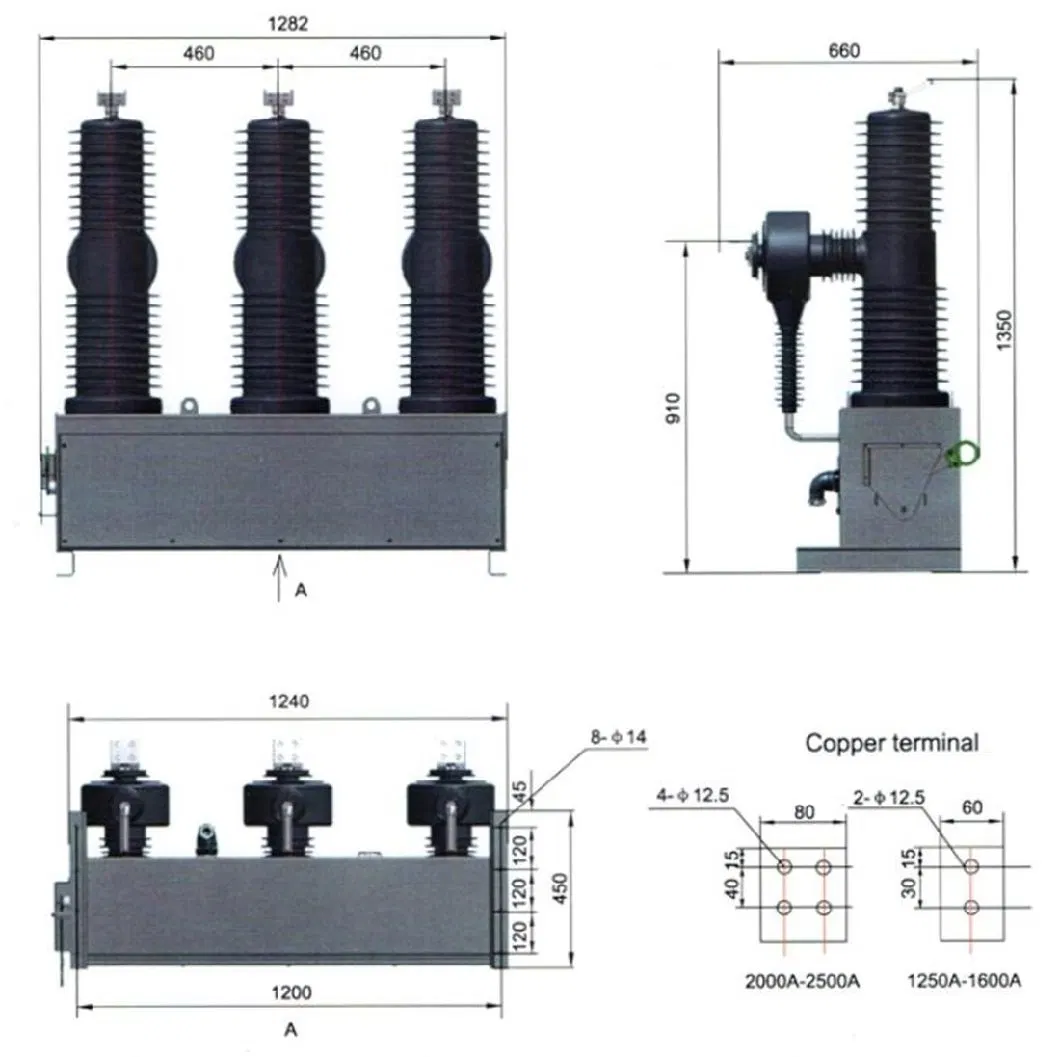

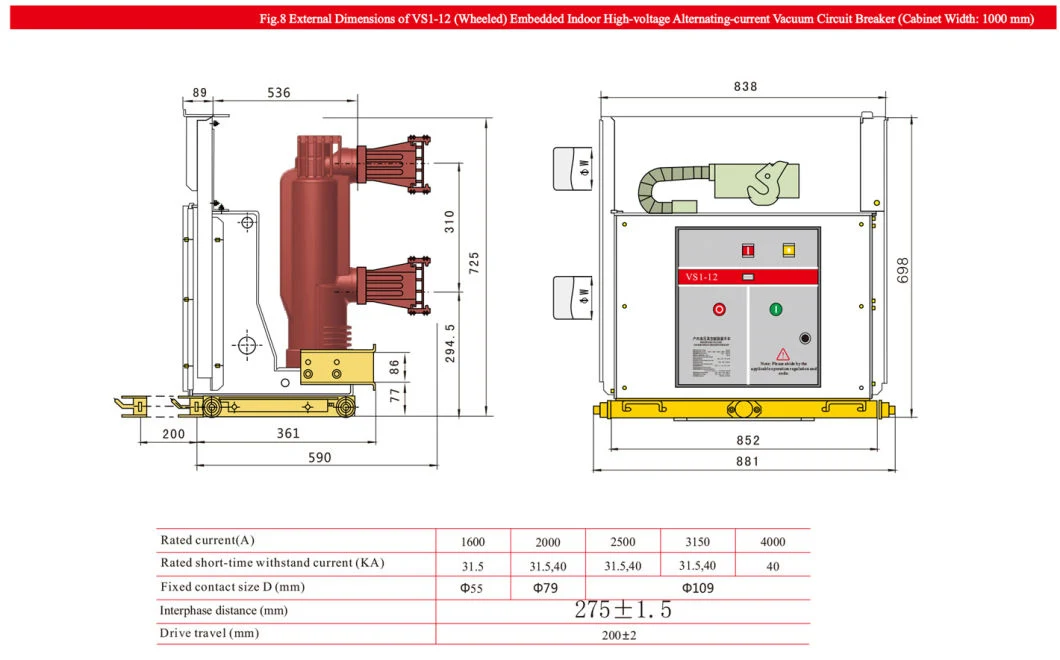

Model explanation:

VS1 - Product code

12 - 12KV

T - Spring Mechanism; M - Permanent Magnetic Mechanism

630 - 630A

25 - 25kA

W - Withdrawable type; F - Fixed type

150 - 150mm pole distance; 210 - 210mm pole distance; 1000 - 1000mm/1m pole distance

P - Potted type; E - Encapsulted type

| VS1-12 Series Indoor High Voltage Vacuum Circuit Breaker | ||||||

| Model | Pole Distance (mm) | Rated Current (A) | Breaking Short-Circuit Capacity (kA) | Installation method | Note | Mechanism |

| VS1-12/T630-25KA-W150P | 150 | 630 | 25 | Withdrawable type | Potted type | Spring |

| VS1-12/T1250-25KA-W150P | 150 | 1250 | 25 | Withdrawable type | Potted type | Spring |

| VS1-12/T1250-31.5KA-W150P | 150 | 1250 | 31.5 | Withdrawable type | Potted type | Spring |

| VS1-12/T630-25KA-F150P | 150 | 630 | 25 | Fixed type | Potted type | Spring |

| VS1-12/T1250-25KA-F150P | 150 | 1250 | 25 | Fixed type | Potted type | Spring |

| VS1-12/T1250-31.5KA-F150P | 150 | 1250 | 31.5 | Fixed type | Potted type | Spring |

| VS1-12/T630-25KA-W150E | 150 | 630 | 25 | Withdrawable type | Encapsulated type | Spring |

| VS1-12/T1250-25KA-W150E | 150 | 1250 | 25 | Withdrawable type | Encapsulated type | Spring |

| VS1-12/T1250-31.5KA-W150E | 150 | 1250 | 31.5 | Withdrawable type | Encapsulated type | Spring |

| VS1-12/T1600-31.5KA-W150E | 150 | 1600 | 31.5 | Withdrawable type | Encapsulated type | Spring |

| VS1-12/T630-25KA-F150E | 150 | 630 | 25 | Fixed type | Encapsulated type | Spring |

| VS1-12/T1250-25KA-F150E | 150 | 1250 | 25 | Fixed type | Encapsulated type | Spring |

| VS1-12/T1250-31.5KA-F150E | 150 | 1250 | 31.5 | Fixed type | Encapsulated type | Spring |

| VS1-12/T1600-31.5KA-F150E | 150 | 1600 | 31.5 | Fixed type | Encapsulated type | Spring |

| VS1-12/T630-20KA-W210P | 210 | 630 | 20 | Withdrawable type | Potted type | Spring |

| VS1-12/T630-25KA-W210P | 210 | 630 | 25 | Withdrawable type | Potted type | Spring |

| VS1-12/T1250-25KA-W210P | 210 | 1250 | 25 | Withdrawable type | Potted type | Spring |

| VS1-12/T1250-31.5KA-W210P | 210 | 1250 | 31.5 | Withdrawable type | Potted type | Spring |

| VS1-12/T1600-31.5-W210P | 210 | 1600 | 31.5 | Withdrawable type | Potted type | Spring |

| VS1-12/T2000-31.5-W1000P | 1000 | 2000 | 31.5 | Withdrawable type | Potted type | Spring |

| VS1-12/T2000-40-W1000P | 1000 | 2000 | 40 | Withdrawable type | Potted type | Spring |

| VS1-12/T2500-31.5-W1000P | 1000 | 2500 | 31.5 | Withdrawable type | Potted type | Spring |

| VS1-12/T3150-31.5-W1000P | 1000 | 3150 | 31.5 | Withdrawable type | Potted type | Spring |

| VS1-12/T3150-40-W1000P | 1000 | 3150 | 40 | Withdrawable type | Potted type | Spring |

| VS1-12/T4000-31.5-W1000P | 1000 | 4000 | 31.5 | Withdrawable type | Potted type | Spring |

| VS1-12/T630-20KA-F210P | 210 | 630 | 20 | Fixed type | Potted type | Spring |

| VS1-12/T630-25KA-F210P | 210 | 630 | 25 | Fixed type | Potted type | Spring |

| VS1-12/T1250-25-F210P | 210 | 1250 | 25 | Fixed type | Potted type | Spring |

| VS1-12/T1250-31.5-F210P | 210 | 1250 | 31.5 | Fixed type | Potted type | Spring |

| VS1-12/T1600-31.5-F210P | 210 | 1600 | 31.5 | Fixed type | Potted type | Spring |

| VS1-12/T2000-31.5-F1000P | 1000 | 2000 | 31.5 | Fixed type | Potted type | Spring |

| VS1-12/T2000-40-F1000P | 1000 | 2000 | 40 | Fixed type | Potted type | Spring |

| VS1-12/T2500-31.5-F1000P | 1000 | 2500 | 31.5 | Fixed type | Potted type | Spring |

| VS1-12/T3150-31.5KA-F1000P | 1000 | 3150 | 31.5 | Fixed type | Potted type | Spring |

| VS1-12/T3150-40KA-F1000P | 1000 | 3150 | 40 | Fixed type | Potted type | Spring |

| VS1-12/T630-20KA-W210E | 210 | 630 | 20 | Withdrawable type | Encapsulated type | Spring |

| VS1-12/T630-25KA-W210E | 210 | 630 | 25 | Withdrawable type | Encapsulated type | Spring |

| VS1-12/T1250-25KA-W210E | 210 | 1250 | 25 | Withdrawable type | Encapsulated type | Spring |

| VS1-12/T1250-31.5KA-W210E | 210 | 1250 | 31.5 | Withdrawable type | Encapsulated type | Spring |

| VS1-12/T1600-31.5-W210E | 210 | 1600 | 31.5 | Withdrawable type | Encapsulated type | Spring |

| VS1-12/T1600-31.5-W275E | 275 | 1600 | 31.5 | Withdrawable type | Encapsulated type | Spring |

| VS1-12/T2000-31.5-W1000E | 1000 | 2000 | 31.5 | Withdrawable type | Encapsulated type | Spring |

| VS1-12/T2000-40-W1000E | 1000 | 2000 | 40 | Withdrawable type | Encapsulated type | Spring |

| VS1-12/T2500-31.5-W1000E | 1000 | 2500 | 31.5 | Withdrawable type | Encapsulated type | Spring |

| VS1-12/T3150-31.5-W1000E | 1000 | 3150 | 31.5 | Withdrawable type | Encapsulated type | Spring |

| VS1-12/T3150-40-W1000E | 1000 | 3150 | 40 | Withdrawable type | Encapsulated type | Spring |

| VS1-12/T4000-31.5-W1000E | 1000 | 4000 | 31.5 | Withdrawable type | Encapsulated type | Spring |

| VS1-12/T4000-40-W1000E | 1000 | 4000 | 40 | Withdrawable type | Encapsulated type | Spring |

| VS1-12/T630-25KA-F210E | 210 | 630 | 25 | Fixed type | Encapsulated type | Spring |

| VS1-12/T1250-25-F210E | 210 | 1250 | 25 | Fixed type | Encapsulated type | Spring |

| VS1-12/T1250-31.5-F210E | 210 | 1250 | 31.5 | Fixed type | Encapsulated type | Spring |

| VS1-12/T1600-31.5-F210E | 210 | 1600 | 31.5 | Fixed type | Encapsulated type | Spring |

| VS1-12/T1600-31.5-F275E | 275 | 1600 | 31.5 | Fixed type | Encapsulated type | Spring |

| VS1-12/T2000-31.5-F1000E | 1000 | 2000 | 31.5 | Fixed type | Encapsulated type | Spring |

| VS1-12/T2000-40-F1000E | 1000 | 2000 | 40 | Fixed type | Encapsulated type | Spring |

| VS1-12/T2500-31.5-F1000E | 1000 | 2500 | 31.5 | Fixed type | Encapsulated type | Spring |

| VS1-12/T3150-31.5KA-F1000E | 1000 | 3150 | 31.5 | Fixed type | Encapsulated type | Spring |

| VS1-12/T3150-40KA-F1000E | 1000 | 3150 | 40 | Fixed type | Encapsulated type | Spring |

| VS1-12/T4000A-31.5KA-F1000E | 1000 | 4000 | 31.5 | Fixed type | Encapsulated type | Spring |

| VS1-12/T4000A-40KA-F1000E | 1000 | 4000 | 40 | Fixed type | Encapsulated type | Spring |

| Main Technical Parameters | ||

| Item | Unit | Data |

| Rated voltage | kV | 12 |

| Rated frequency | Hz | 50 |

| Rated insulation level 1 min power frequency withstand voltage pole to earth | kV | 42 |

| Rated insulation level 1 min power frequency withstand voltage phase | kV | 48 |

| Rated insulation level lightning impulse withstand voltage pole to earth | kV | 75 |

| Rated insulation level lightning impulse withstand voltage phase | kV | 85 |

| Power frequency withstand voltage of secondary circuit | V | 2000 |

| Rated current | A | 630,1250, 1600, 2000, 2500, 3150, 4000, 5000 |

| Rated short-circuit breaking current | kA | 20, 25, 31.5, 40, 50 |

| Rated short-time withstand current | kA | 20, 25, 31.5, 40, 50 |

| Rated short circuit duration | s | 4 |

| Rated peak withstand current | kA | 50, 63, 80, 100, 125 |

| Rated short-circuit making current | kA | 50, 63, 80, 100, 125 |

| Rated short circuit current breaking times (class E2) | times | 30 |

| Rated single/back to back capacitor bank breaking current | A | 630/400, 800/400 |

| Clearance between open contacts | mm | 11±1 |

| Contact stroke | mm | 3~4 |

| Allowable wear thickness of contact | mm | 3 |

| Average opening speed | m/s | 0.9~1.4 |

| Average closing speed | m/s | 0.5~1.0 |

| Contact closing bounce time | ms | ≤2 |

| Different phases of contact closing and opening | ms | ≤2 |

| Rebound amplitude of opening contact | mm | ≤2 |

| Opening time (rated voltage) | ms | 20~50 |

| Closing time (rated voltage) | ms | 30~70 |

| Mechanical life (M2) | ms | 10,000(20,000) |

| Rated operating voltage | V | AC110/220 DC110/220 |

| Rated operation sequence | O-0-CO-180s-CO | |

First of all, the first step in the manufacture of vacuum circuit breakers is to select materials. The choice of material is very important, because the vacuum circuit breaker needs to have good insulation properties and mechanical strength, it can bear affected by high voltage and high short circuit current. Common materials are copper, steel and ceramics.

The next step is the processing of the parts. The vacuum circuit breaker consists of many parts, including circuit breaker body, mechanical motion mechanism, electromagnetic components, etc. These parts need to be imported line accurate machining and assembly to ensure its reliability and stability.

After the parts are processed, the assembly of the vacuum circuit breaker can begin.

First of all, each part is assembled on the circuit breaker body, and debugging and calibration.

Next, the electromagnetic component is installed in the appropriate position and the control line is connected. In addition, it is also necessary to

adjust and test the mechanical motion mechanism to ensure its sensitivity and smoothness how free it is.

After the assembly is completed, the vacuum circuit breaker can be tested and inspected. Through split the router conducts electrical characteristic tests, such as breakdown voltage test, breaking and closing test, etc.

To ensure that it meets design requirements and standards. At the same time, the appearance quality check is also required

and performance testing to ensure the quality and reliability of the circuit breaker.

Finally, after rigorous testing and inspection, the vacuum circuit breaker can be packed and processed leaves factory. Take anti-shock, moisture-proof, and anti-static measures to protect the circuit breaker integrity and security. The label and instruction manual should also be accurately affixed to the package to facilitate the user to understand and use.

In general, the process of vacuum circuit breaker includes material selection, parts processing, assembly, testing and inspection, packaging and delivery. Every step needs to be strict control and operate to ensure product quality and safety. Only through fine craftsmanship process, in order to create a high-quality vacuum circuit breaker for the stable operation of the power system and equipment protection to provide assurance.

Vacuum circuit breaker is widely used in power system.

The working principle of the vacuum circuit breaker is:

When the dynamic and static contacts are opened under the action of the operating mechanism, an arc is generated between the contacts, and the surface of the contacts evaporates steam at high temperature. Due to the special shape of the contacts, a magnetic field is generated when the current passes through, and the arc moves rapidly along the tangential direction of the surface of the contacts under the action of this magnetic field, and part of the metal steam condenses on the metal cylinder (shielding cover). The arc is extinguished at the natural zero, and the strength of the medium between the contacts quickly recovers.

You can rest assured that the packaging of the product, as the last link we strictly control!

Hebei Leicheng Power Technology Co., Ltd. is a professional engaged in power transformers, high and low voltage switchgear and related products R & D, production, sales and service of science and technology enterprises.

Hebei Leicheng Power Technology Co., Ltd. is a professional engaged in power transformers, high and low voltage switchgear and related products R & D, production, sales and service of science and technology enterprises.

Since its establishment, the company has been committed to the road of professional development. With strong technical force, advanced equipment at home and abroad, innovative concept and rich manufacturing experience, has passed ISO9000 certification, the use of CAD, to provide customers with suitable regional characteristics of environmental protection, energy saving, low-carbon, high-quality products to meet the basic requirements of the market and different customers. Products are also exported to Central Asia, Africa, Southeast Asia, the Middle East, South America and other countries and regions.

At present, the company mainly produces high voltage/low voltage distribution cabinets, prefabricated substations, distribution transformers, high voltage/low voltage switches and other products.

Various power fittings and accessories, such as transformer support frame, cable hoop, bolt, wire clamp, cross arm and other products are numerous.

Steel products, such as H-shaped steel, channel steel, steel pipe, Angle steel, hot dip galvanized iron wire, etc., are also our main products!

Welcome to shop! Contact me for more product information!

Q: Are you a Manufacturer, factory or Trading company ?

A: Yes, We are engaging in the research and development, production and operation of transformer for over 10 years.

Q: What's your warranty terms?

A: We offer 12 months warranty time.

Q: Production Time?

A: In general, it take 4~6weeks and it depend on the different style.

Q: What's your payment terms?

A: Pay by T/T and L/C is acceptable.

Q: How do you conduct quality control in your factory?

A: We implement 100% QC inspection to ensure every product is qualified. We have over 10 times QC inspections during the manufacturing process from raw material to the final products.Each of our unit has 3C certificate. If you need any other Certificate, we can help you to apply it.

Q: Do you have the products in stock?

A: Normally no. All our products produce depending to your order quantity.

Q: What should provide to make custom transformer ?

A: Technical drawing and technical specification document are the best, or you can tell us some details technical specification date as below "Quotation and Ordering Required Information".

Q: Could I have your catalog and price list for trial order in MOQ quantity?

A: All of our products are showing on Made-in-China or official website, you are always welcome to ask us to get more information directly.

Our plants produce all types of transformers and related power equipment, including substations, capacitor cabinets, header cabinets, dry transformers and more. Related products can be found on our home page, or contact me directly, let me help you!

Welcome to our homepage to see more content!